Extraction methods

To satisfy rigorous quality control requirements, you will find on our labels the method by which the plant has been extracted, symbolized by the letter below, indicated in upper case between parentheses.

For Essential Oils and Essences

From the essence to the essential oil

Numerous techniques are used to extract the aromatic molecules. This delicate and sensitive process was developed over many years and are still being perfected by modern technologies to extract these precious essences that nature has so meticulously produced. Imagine the volatile nature of a flower’s delicate perfume and the complexity of capturing it in a small bottle. The goal is to extract the original essence in its integrity.

Current extraction techniques

The technique will vary according to the type of plant, the quality that is desired and the intended use. This, along with the ratio of raw material it takes to obtain the essential oil, the cost of acquiring the plants, and the amount of time can greatly influence the price of the final product.

Distillation (D)

The Egyptians and Persians were the first to develop distillation techniques around 3000 years ago. Later, this method was used by the Arabs and more recently perfected by the masters in Grasse. The ratio of essential oil extracted can vary greatly according to the plant distilled. Today, the most common method of producing essential oils is steam distillation.

Steam distillation can be divided into 3 categories :

1) Steam distillation

|

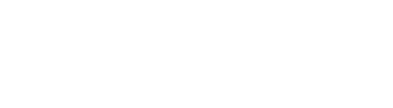

| First steam distillation technique |

The first and most ancient technique entails placing an alambic over a fire or heat source, filling it with 2 parts water and up to 6 parts raw plant material that are placed on a screen above the water, and heating the water so that it produces steam, without allowing the temperature to climb over 100 degrees celsius. The steam rises through the raw material, opening all of the little “pockets” containing the plant’s aromatic molecules, releasing them. The steam carries the essence through a condensing coil and we collect the liquid in a special container.

We can observe at this point that there are 2 distinct layers of liquid. The essential oil, usually lighter than water and hydrophobic, floats on top and the re-condensed steam which has acquired some of the properties and a light aroma is at the bottom. It is this water that we call a hydrolat, hydrosol or floral water.

2) Injected steam distillation

|

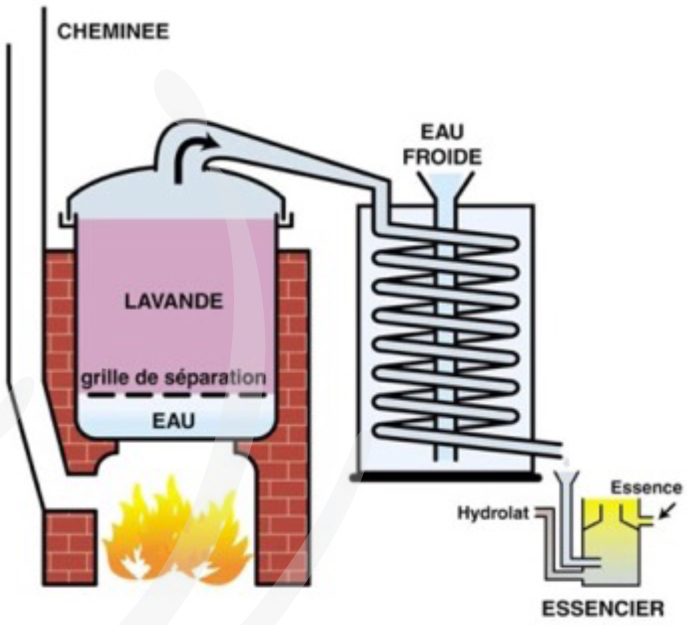

| Modern steam distillation technique |

The second method is a more modern version of the first technique. It follows the same principles, however the water is heated in a separate recipient and the steam is carried through pipes to an adjoining container which contains the raw material to be distilled. The vapour is injected at the base of the tank and rises through the plants before passing through a condensing coil. This technique allows us to limit the alteration of the essential oils and is considered for this reason to produce a higher quality product.

3) Percolation

The third technique is called percolation and uses gravity to help the process along. A variant on the second technique, the steam is injected at the top of the tank and and passes down through the plant material. This method is used only with specific types of plants and can present the advantage of being quicker than traditional steam distillation, which can mean less transformation. The final product, however, contains non-volatile substances as well as the essential oil and is sometimes referred to as a percolation essence rather than an essential oil. Another technique can then be used to separate the volatile molecules from the rest of the percolation essence to obtain the essential oil.

Cold Pressed (E)

This technique is reserved mainly for the fruits of the citrus family. We press the fruit to extract the aromatic essence from the zest or peel. The final product is less stable and more vulnerable to oxidization than steam-distilled oils, Therefore is is generally recommended to use them more quickly, ideally within a year. Although commonly called essential oils, certain schools reserve that term solely for the products of steam distillation.

Solvant Extraction (S)

This type of extraction is used for certain plants such as jasmine (jasminum officinale) which are too delicate to be heated and their aroma would be lost, or for plants like the rose (rosa centifolia) that contain such a small quantity of aromatic molecules that it is more cost effective to use this method of extraction.

This method, appearing in the 18th century, originally used ether as a solvent, but because of its high flammability and cost, in recent years producers use more appropriate solvents such as hexane and ethanol.

To extract the aromatic essence, the raw material is placed in a steel tank and is washed many times with the solvent, which accumulates more and more of the aromatic molecules as well as the waxes, resins and pigments of the plant. After decanting, filtering, evaporation of the solvent, it is placed in a low-pressure tank and when cooled, the concentrated extract solidifies into a very aromatic wax-like solid that we call a concrete. With further washes in alcohol, successive coolings, filtration and evaporation of the alcohol, the concrete is transformed into a pure essence known as an absolute.

Supercritical CO2 Extraction (Supercritical Fluid Extraction)

|

|

Supercritical CO2 Extraction |

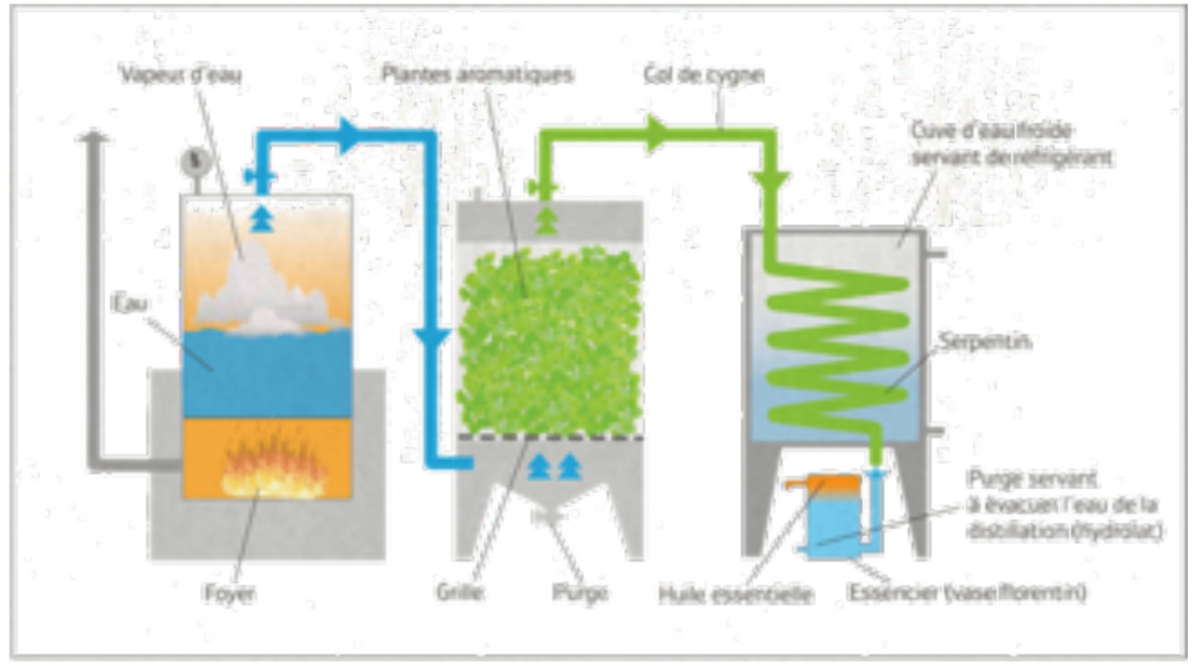

One of the most recent techniques developed, it is considered most promising for the range of molecules than can be extracted and the integrity of the final product. Super critical C02 is becoming popular as a solvent for its low toxicity and low environmental impact. It is natural, chemically inert, non-flammable, readily available and inexpensive However, it remains for the moment, extremely difficult and costly to operate and maintain the equipment.

The technique consists of injecting a flow of supercritical CO2 (which entails maintaining carbon dioxide at a pressure and temperature at or above its critical point, a state in which it acts midway between a gas and a liquid) into a sealed tank containing the raw material. The increase in pressure causes the “pockets” of aromatic molecules to break open, releasing their contents into the carbon dioxide. The fluid then passes into another chamber at a lower pressure (usually atmospheric) causing the carbon dioxide to return to its gaseous state and a precipitation of the aromatic molecules into a recipient where it can then be collected.

For Carrier oils & Macerations

Cold pressed (HV)

The majority of our carrier oils are cold pressed which means the seed or fruit is mechanically pressed at room temperature to extract their oil while preserving all of their qualities and nutrients. This oil contains all of the essential nutrients of the plants. Virgin, our oils have undergone no chemical treatments or refining processes with exception for filtration and centrifugation.

Macerations (MA)

This is an ancient technique that consists of placing raw material (usually flowers) in an container of oil and allowing the mix to sit in the sun anywhere from a few weeks to several months before filtering, so the oil is infused with the properties of the plant in question. Flowers such as calendula, St John’s wort and arnica are common choices for their various therapeutic qualities and the “floral oil” can then be used either as is, or in the creation of balms, lotions and blends to treat a variety of ailments.

|

Subscribe to our newsletter here!

All rights reserved © 2024 - ZAYAT AROMA

Terms & conditions | Security & privacy